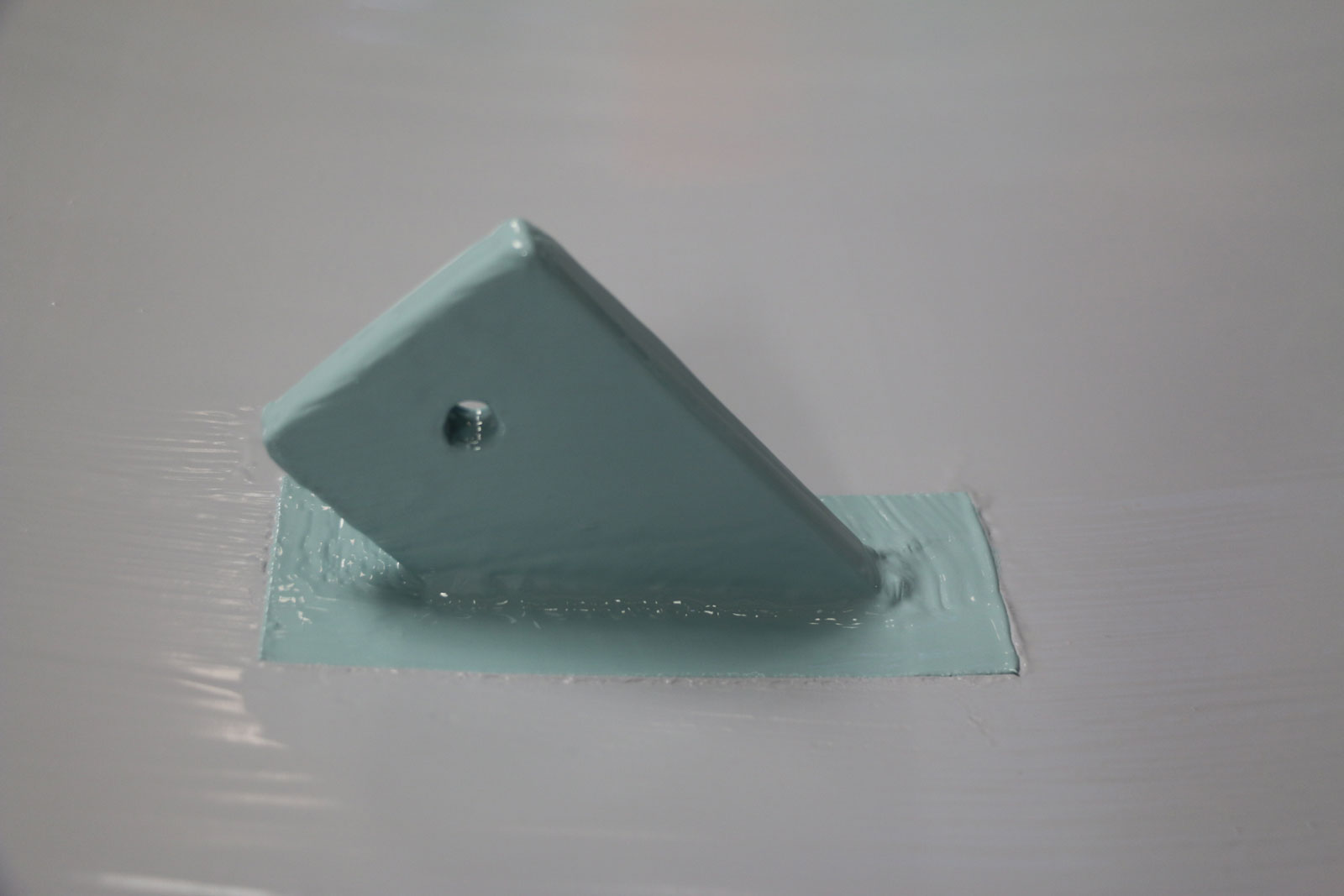

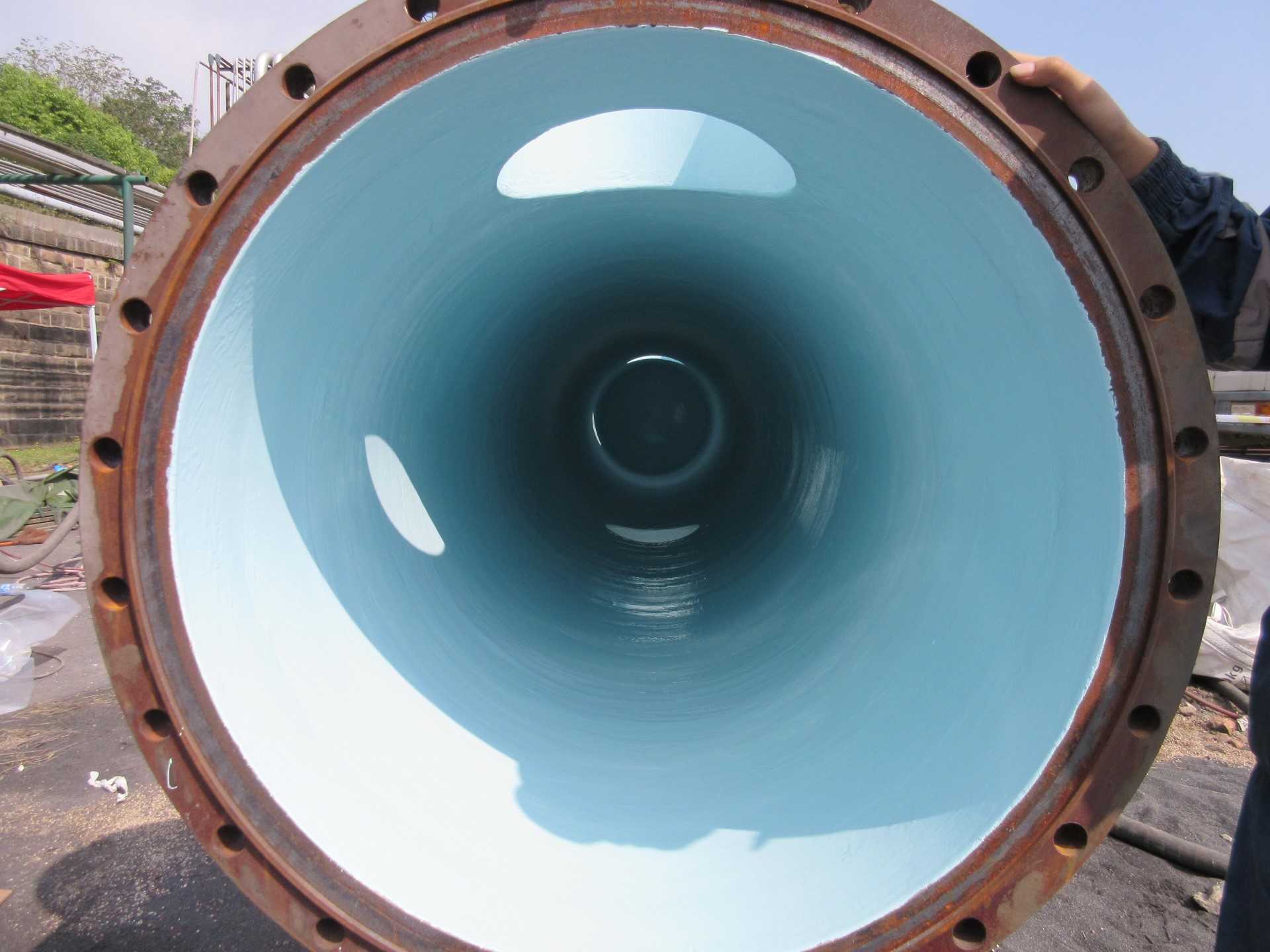

A 2-part hand-applied epoxy coating designed to provide long-term corrosion and chemical resistance to equipment operating in continuous immersion at temperatures up to 160°C (320°F). This coating has a long overcoat window and its cold curing mechanism with full in service cure reduces downtime and ensures rapid return of equipment to service.

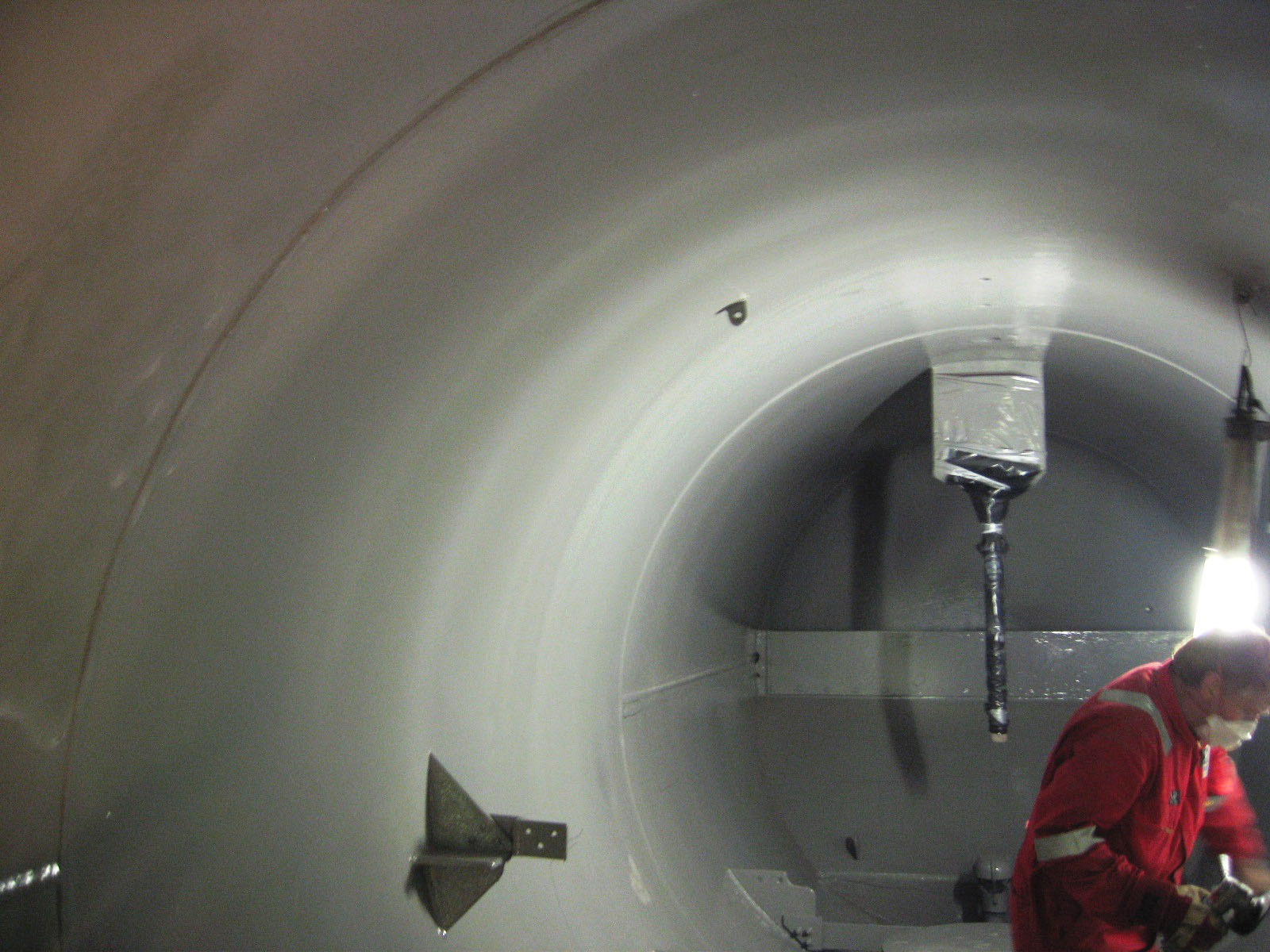

This solvent-free coating is easy to mix and apply without the need for specialist tools, ensuring a simple and safe application in confined areas.